Cymatic Vibration Motor

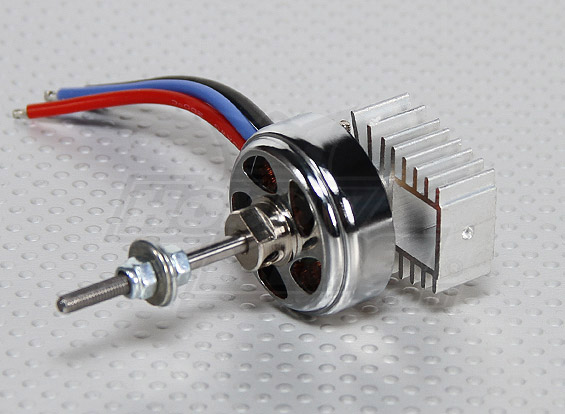

Brushless DC Motor

Make a variable speed vibration motor using an arduino and a tinyESC v2

tinyESC v2 - Brushless Speed Controller

sparkfun page tinyESC v2 - Brushed Speed Controller

FingerTech tinyESC v2

fingertechrobotics.com page FingerTech tinyESC v2

| R/C Stick | Arduino Pulse | Motor Output | LED status |

|---|---|---|---|

| Full Forward | 2000µs | Full Forward | Solid Green |

| Forward | 1510-2000µs | Forward | Flashing Green |

| Centered | 1500µs (+/-10µs deadband) | Off | Either LED Could Flash |

| Backward | 1000-1490µs | Backward | Flashing Red |

| Full Backward | 1000µs | Full Backward | Solid Red |

| No R/C Signal | No Pulse Stream | Off (Failsafe) | Slow Blinking Red |

Combat Zone Review by Thomas Kenney

SparkFun TinyESC demo SparkFun 12-12-14 Product Showcase: Dial R for Resistance

Arduino ESC research

ESC Calibration & Programming

Mechatronics Project Site for SEng466 at the University of Victoria

The PWM signal read by the ESC is the same type as a servo signal, meaning the Servo library from Adruino can be used to calibrate and control the ESCs. The ESC sets the speed of the motor depending on the ratio of high to low signals. Calibration involves programming the ESC to understand the PWM waves corresponding to the stop and maximum speeds of the motor.

The default signal range for most servo motors and ESCs is a high signal width between 1000 and 2000 microseconds over a repetition period of 20 milliseconds (assuming a 50hz PWM signal). For the quad copter, however, we want the range to be as wide as possible to allow for greater incremental control of the motor. To this end, we calibrated the ESCs to read a signal width from 700 to 2000 microseconds with 700 being the stop speed and 2000 being the max speed. We found that the ESC could not read a signal lower than 700 microseconds.

Calibrating the Mystery ESCs was quite simple. To enter programming mode, the maximum servo signal (2000 microseconds) is sent to the ESC, the ESC is powered on and waits for two seconds, then the minimum servo signal is sent (700 microseconds). Once the ESC emits a series of confirmation beeps (special wave signals sent to the motor to emit beeping sounds), the ESC is calibrated.

Arduino - Control ESC/Motor Tutorial

techvalleyprojects - Arduino - Control ESC/Motor Tutorial

Summary

This is a tutorial of how to control an electronic speed control (ESC) and brushless motor using an Arduino.

Description

This tutorial is about controlling a brushless motor, the type commonly used in RC hobbies, and controlling the motor using an Arduino. The goal is to use the Arduino Servo library, give an input from 0 to 180, and see the motor move based on our input.

ESC Programming on Arduino (Hobbyking ESC)

ESC Programming on Arduino (Hobbyking ESC)

How to control a brushless motor through a ESC with Arduino

dronesandrovs article How to control a brushless motor through a ESC with Arduino

A ESC is made to receive inputs from a R/C transmitter, so it works as a servo: to control it you can use the Arduino Servo Library, so the test code is based on the servo library basic example published on the Arduino site.

Kyle Fieldus - Controlling an ESC using an Arduino

youtube Kyle Fieldus - Controlling an ESC using an Arduino

Painless360 - RC Basics - Understanding Electronic Speed Controllers (ESC)

youtube RC Basics - Understanding Electronic Speed Controllers (ESC)

- ESC --- Brushless Motor

youtube Maker Hangar: Episode 3 - Electric Speed Controllers

Brushless DC Motor Research

BLDC Motor Introduction

The Brushless DC (BLDC) motor is the ideal choice for applications that require high reliability, high efficiency, and high power-to-volume ratio. Generally speaking, a BLDC motor is considered to be a high performance motor that is capable of providing large amounts of torque over a vast speed range. BLDC motors are a derivative of the most commonly used DC motor, the brushed DC motor, and they share the same torque and speed performance curve characteristics. The major difference between the two is the use of brushes. BLDC motors do not have brushes (hence the name “brushless DC”) and must be electronically commutated.

BLDC Motor Advantages:

- High Speed Operation – A BLDC motor can operate at speeds above 10,000 rpm under loaded and unloaded conditions.

- Responsiveness & Quick Acceleration – Inner rotor Brushless DC motors have low rotor inertia, allowing them to accelerate, decelerate, and reverse direction quickly.

- High Power Density – BLDC motors have the highest running torque per cubic inch of any DC motor.

- High Reliability – BLDC motors do not have brushes, meaning they are more reliable and have life expectancies of over 10,000 hours. This results in fewer instances of replacement or repair and less overall down time for your project.

himodel.com store

$6.83 - EMAX 1200KV Outrunner Brushless Motors Type CF2822

No. Of cells 2-3 Li-Poly

RPM/V 1200 RMP/V

zMax. efficiency 82%

Max. efficiency current 7 -16 A (>75%)

No load current / 10 V 0.9 A

Current capacity 16 A/60 s

Internal Resistance 150 mohm

Stator Dimensions 22x10 mm

Shaft diameter 3 mm

Weight 39 g

hobbyking.com Store

AX 2306N 2000kv brushless Micro Motor $6.47

AX-2306N-2000

Micro brushless motor

Comes with stick mount, as shown.

Spec.

Kv: 2000rpm/v

Lipo Range: 2-3 cell

Suggested prop: 5x3

Best current range: 6~9A

Weight: 37g

Stator: 23 x 6mm

Test Data.

Battery: 11.5v

Current: 7.3A

Propeller: 5x3

Thrust: 357g

Speed: 19340rpm

hobbyexpress.com motor store

eRC 12A Brushless Programmable ESC w/BEC

280 Size Brushless Outrunner, 2000Kv

Technical Specifications:

KV: 2000 Kv

Voltage Range: 7.4V

Max Amperage: 12 Amps

Weight: 22g

Propeller Size: 8x3.8

.25 Size Brushless Outrunner, 850Kv

$35 at hobbyexpress.com .25 Size Brushless Outrunner, 850Kv

Quality brushless outrunners at a budget price

eRC Brushless ESC’s from Hobby-Lobby37mm dia. x 40mm long excluding the 19mm long, 5mm diameter shaft. 4mm gold plated connectors and collet prop adapter with 8mm shaft. Economically priced HIGH power brushless outrunner motors. There is a motor for almost any airplane from a parkflyer up to a.60 size glow model. Each motor comes complete with mounting hardware, collet prop adapter and gold plated electrical connections. The motor connections are pre-installed and their mating connectors included for your speed control. All motors are produced in a state-of-the-art factory with strict quality control assuring you a long motor life and excellent performance. Each motor comes with a 1-year warranty against manufacturer’s defects.

Technical Specifications:

Motor Diameter: 37mm

Shaft Diameter: 5mm

KV: 850 Kv

Voltage Range: 7.4V - 14.4V

Max Amperage: 40 Amps

Weight: 4.9 oz.

Propeller Size: 11x5

Brushed DC motor

Adafruit DRV8871

Brushed DC motor driver

adafruit product page Adafruit DRV8871 DC Motor Driver Breakout Board - 3.6A Max $7.50

Crank up your robotics with powerful Adafruit DRV8871 motor driver breakout board. This motor driver has a lot of great specs that make it useful for a wide variety of mechatronics. In particular, the simple resistor-set current limiting and auto-magic PWM support make it super easy to use with just about any brushed DC motor.

Check out the specs for the DRV8871:

- 6.5V to 45V motor power voltage

- Up to 5.5V logic level on IN pins

- 565mΩ Typical RDS(on) (high + low)

- 3.6A peak current

- PWM control

- Current limiting/regulation without an inline sense resistor

- Undervoltage lockout

- Overcurrent protection

- Thermal shutdown

learn.adafruit.com article Brushed DC Motor Control

Simple Speed Control

If all you need is speed control, you can drive a motor with a PWM pin and a simple transistor circuit. The PWM pin controls the transistor which switches the current to the motor. The higher the PWM duty cycle, the faster the motor will go.

Adafruit Motor shield kit

Adafruit product page Adafruit Motor/Stepper/Servo Shield for Arduino v2 Kit - v2.3

Sand Sieve Ideas

General Research

electricaleasy.com article Speed control methods of DC motor

precisionmicrodrives.com/vibration-motors

precisionmicrodrives.com Brushless BLDC Vibration Motors

instructables.com Simple, Cheap Motor Controller by TeamJaeger

tachometer

ServoCity

Vibration sensor

sparkfun Piezo Vibration Sensor

sparkfun Piezo Vibration Sensor - Large

SparkFun Single Axis Accelerometer

SparkFun Single Axis Accelerometer Breakout - ADXL193 (+/-250g)

RS Cymatics

youtube RS Cymatics - Bubble Cymatics - A New Experiment 2014