Quadra-Fire Stove

Serial # 0143978

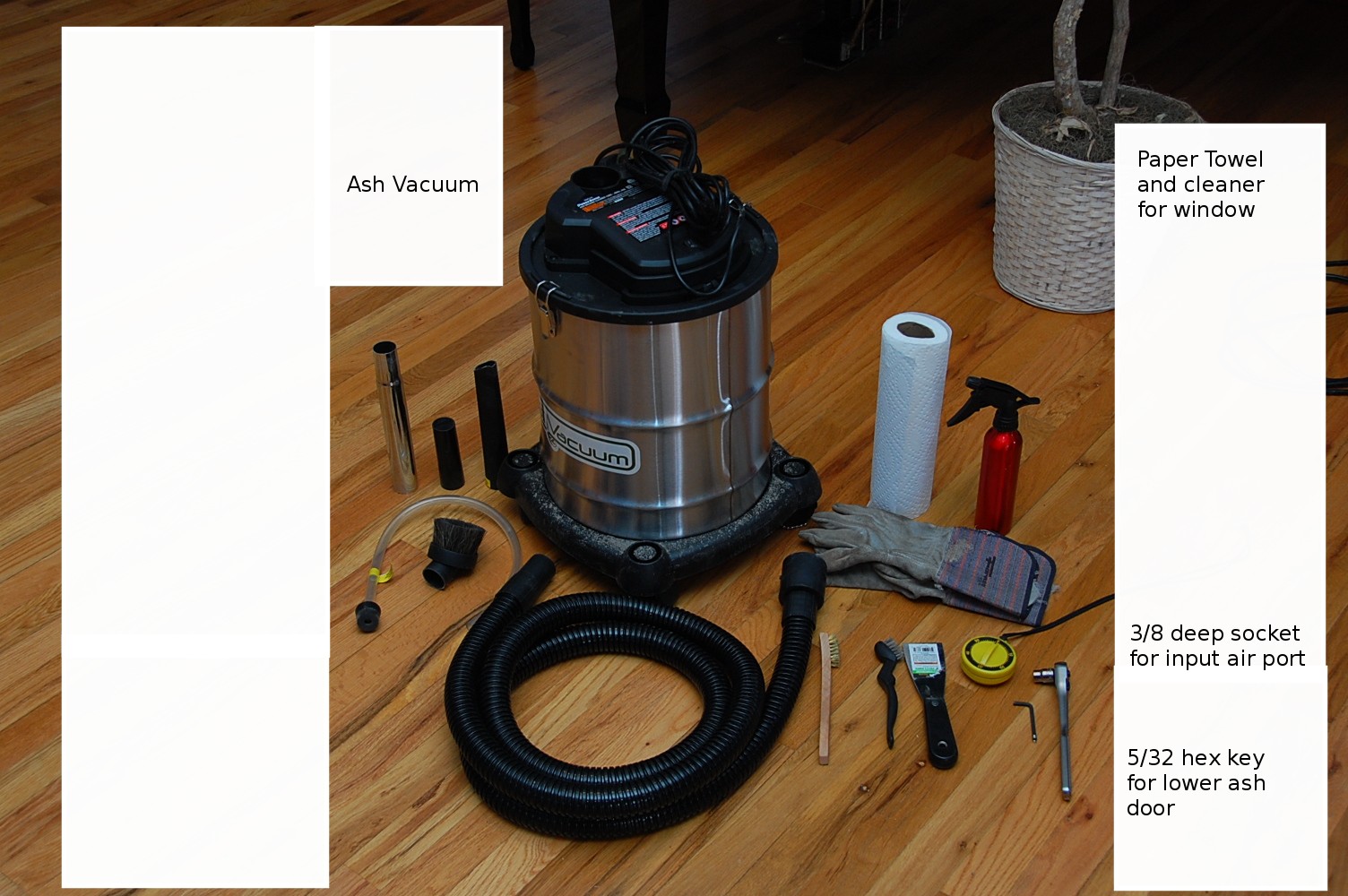

Tools

5/32 hex key to open door to expose bottom of fireput

3/8 socket/wrench to loosen air vent adjustable cover

7/16 for bolt holding fire pot

Looking for 3/8 deep socket to attach to screw driver. Access to the 3/8 nut on the air vent will work best with a screwdriver handle.

10 Pc 1/4 in. Drive SAE High Visibility Deep Socket Pittsburgh Professional - item#67876 $10 at harbor freight

- 3/16 in.

- 7/32 in.

- 1/4 in.

- 9/32 in.

- 5/16 in.

- 11/32 in.

- 3/8 in.

- 7/16 in.

- 1/2 in.

- 9/16 in.

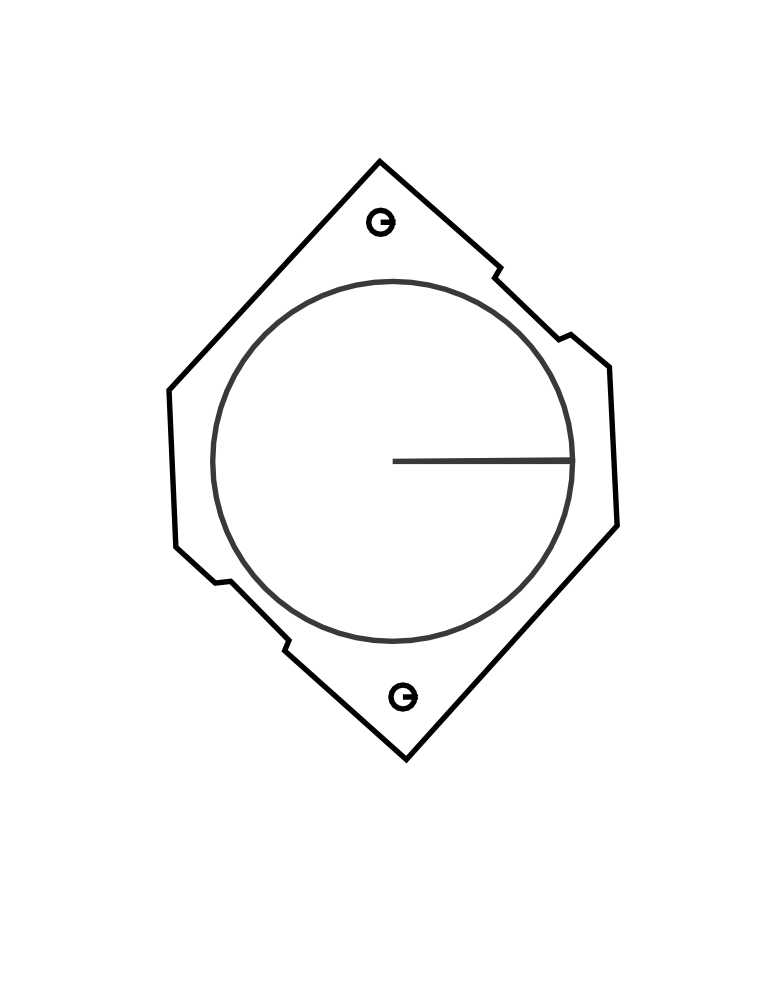

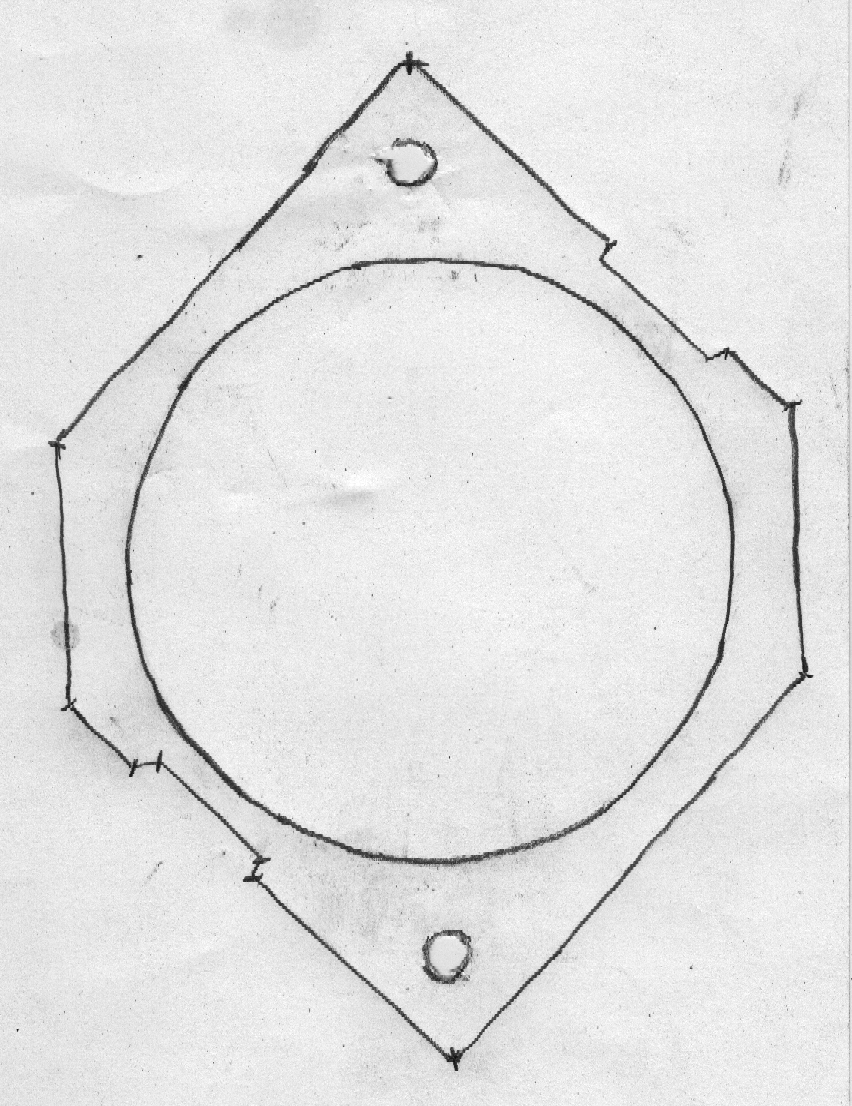

exhaust gasket template

stove-gasket-vector.png

stove-gasket-template-scan.png

stove-gasket-vector.svg

Scott Maxwell - Chimney Sweep

719-696-5260 mobile for contact

719-583-0720 leave message

Local user manual

p. 7 - venting illustrations

p. 9 - Thermostat installation

p.10 - Venting chart

p.11 - Feed Adjustment Instructions

p.12 - Operating Instructions

p.13 - Cleaning and Maintenance

p.14 - Reading the fire and adjustment procedures

p.15 - Component information

p.17 - Troubleshooting

1100i service marts manual - local

Flue Flange Gasket , Wing 812-1300

Wood Heat Stoves youtube Quadra-Fire 1100-I pellet stove insert operation and maintenance manual video

1:00 - Automatic ignition

1:45 - stove gets a call from the thermostat

timers run stove until it reaches a certain temperature

stays running by temperature and thermostat demand

returns to times for shutdown

red call light shows demand for heat.

2:08 thermostat calls for heat. The call light (red) comes on.

2:15 - exhaust blower comes on creating a partial vacuum in the burn-pot

the feed motor starts and feeds a few pellets

the ignitor comes on

a low flame sends reading of 200deg. to the control box

if this happens within 2 minutes the ignitor will turn off

and the feed motor will continue to turn

if 200deg. is not reached the feed motor will stop

but the igniter will stay on for four more minutes

green light comes on at 200deg. red light at 1000deg.

3:40 - the shutdown sequence is also timed.

thermostat call goes off, red light goes off, shutdown sequence started

the feed motor stops

exhaust blower runs for 8 minutes, exhausting the remaining fuel in the fire-pot

the exhaust fan shuts off until the thermostat calls for heat.

4:10 - convection blowers move air over the heat exchanger.

turn on at 125deg. turn off at 105deg.

4:40 - also 3 safety systems.

vacuum switch turns of feed motor if door is open or exhaust is clogged

snap disk that acts as thermostat in case the convection blowers don't start or stop.

another snap disk shuts off if top of feed tube is over 200deg.

5:30 - components

6:00 - heat exchanger cover

feed chute

thermocouple

fire-pot

2 triangular ash pans

heated convection air outlet

left room air intake

another intake on the bottom

side plates removable, held by allen screws

right side top and bottom air intakes

7:15 - hopper lid is adjustable

right side panel exposes snap disk 2

the thermocouple

and small convection motor

8:30 - left side panel is removable and exposes

the exhaust blower and exhaust ducting

orange convection ducting from convection blower to heat exchanger

9:15 - left side removes with 5/32 allen wrench

exposes the feed motor

vacuum tube to vacuum switch

back wall has cover giving access to the exhaust stack

snap disk #3 on feed tube

10:00 large convection blower

capacitors for large convection blower and exhaust blower

on the bottom is the combustion air inlet

10:20 remove right side

2 boxes, top box is control box with temperature indicator lights

bottom box is junction box

on side wall is snap disc #1, controls both convection blowers

behind this is snap disc #2, safety system for too hot

junction box has thermocouple leads, fuse, thermostat leads

12:10 700W of power required

24V AC thermostat

13:00 white (neutral) to top center terminal. red (24V) to bottom center terminal

fuse is standard 7 amp AGC #7 120V fuse

13:55 restart button is beside the call light

when pushed, opens the thermostat circuit

when released it restarts the automatic ignition cycle

this only works when the thermostat is calling for heat

15:00 system pull pellets up the feed tube from the hopper

and drops them down the feed chute into the fire-pot

15:30 fire-pot is made of cast ceramic

designed with air intake holes that swirl the fire

when there is fire in the pot, air from bottom causes cyclone of air

a removable clean-outplug was designed into the fire-pot

16:11 The igniter is made of cast silicon carbide ceramic material

reaches 2500deg.

16:50 thermocouple senses the temperature in the fire-box

200deg. lights green light on control box

1000deg. lights red light on control box

17:20 Blower #1 42CFM

delivers air to a plenum over the fire-box and out the top middle vent

17:40 Blower #2 86CFM on the left

delivers air through ducting and over the heat exchanger fins

and out the bottom 2 vents in the front

driven by 4uF capacitor on the left side of the stove

18:20 exhaust blower access from left rear.

pulls air out of the fire-box through the inside fins on the heat exchanger

driven by 3uF capacitor on the left side

18:55 Vacuum switch. vacuum tube from nipple on feed chute to the vacuum switch

vacuum must be sensed for the feed motor to run. A safety device

19:26 Snap disk #1 - first from the front.

controls convection blowers. on at 125deg. off when temperature falls to 105deg.

19:50 Snap disk #2 - second from the front. 2 yellow leads run from it

an important safety system. opens at 250deg.

20:20 Snap disk #3 - on the feed tube on the left side.

turns stove off if feed tube temperature exceeds 200deg.

pellets combust at ??

20:55 Heat exchanger - aluminum fins in the fire-box at the right side

21:32 Installation tips and adjustment procedures

23:40 Hopper adjustment for installation.

24:18 back of hopper briefly exposed.

24:45 - feed adjustment plate, screw just loose enough to allow adjustment

26:20 - first fire

26:25 - first power, exhaust blower comes on

make sure thremostat is below room temperature

put handful of pellets in fire pot

close and latch door, set thermostat above room temerature

let run for 15 min. to reach operating temperature

2 things necesary.

thermocouple must read 1000deg.

thermostat must be calling for more heat

27:35 - properly adjusted fire

adjust feed adjustment plate

check fire-pot gasket and heat exchanger clean-out door gasket

adjust air adjustment plate

28:54 - shows properly adjust flame - short and active

29:03 - fire is too small

open feed adjustment plate.

if needed close the air adjustment

29:43 - if glass is getting black, fire is probably too high

30:21 - hard wood has high minerals, will generate clinkers

31:04 - buy pellets in muti-ton lots when possible

31:20 - troubleshooting

what shut the stove off?

assume the thermostat is calling for heat ahd the red call light is on.

31:44 - look in the fire-pot to see

31:50 - unburned pellets, stove has simply missed an ignition

33:25 - thermocouple problems

35:50 - door gasket inspection

36:30 - fire pot gasket inspection

36:45 - fire-pot wear - check for holes

37:26 - clean the firepot

38:29 - no cleaning of the igniter is necessary

38:40 - small convection blower checked and cleaned every 6 months

39:05 - large convection blower cleaned once a year

39:20 - clean the exhaust stack

39:50 - parts replacement

the call light is a 28 volt AC bulb number 85 lamp if replacement is necessary remove

24V AC thermostat. .05 amp heat anticipator

41:15 - snap disk #1. marked F125-20

42:00 - snap disk #2. makred L250-40

opens at 250deg. resets when it cools down

test by shorting

42:35 - snap disk #3. marked L200-M

rarely needs replacing. all power goes through it

43:25 - convection blower #1 42cfm

44:30 - convection blower #2 86cfm

47:10 - the switch

48:40 - feed system

woodheatstoves.com

Quadrafire 1100i EBM Exhaust Blower (Motor Only) 812-1110 - $340.00

High temp. tape

CS Hyde High Temperature Fiberglass Tape With Silicone Adhesive, Ivory 1/2 inch x 36 yards $18.44 at amazon

Parts

A-1 Stoves and Fireplaces

a1stoves.com/quadrafire-1100i-insert-parts Quadrafire 1100i Insert Parts

stove-parts-unlimited.com Quadrafire 1100I parts

The Quadrafire 1100I Insert ended production on 5-10-1999 with the last serial number being 150698.

wood-furnaces.net/quadrafire1100ip Quadrafire 1100i/P-28 Combustion/Exhaust Blower - $330

Replace Ignitor

Tue Jan 24 08:53:47 MST 2017

$77 at woodheatstoves.com Quadrafire Pellet Stove Ignitor

Part: SRV7000-462

$77 at woodheatstoves.com

$68.20 at a1stoves.com

$48 at www.stove-parts-unlimited.com

812-3811

Note: This is the Loop Ignitor for the EZ-Clean Burn Pot ONLY. If you

have the Ceramic Burn Pot, you will need the Ceramic Ignitor 812-0180.

$50 at www.stove-parts-unlimited.com

3-5 days for free shipping

Ceramic Igniter for the Quadrafire 800, 1000 and 1100i Pellet Stoves (812-0180) $70 at stove-parts-unlimited.com/ceramic-igniter

Replacement Ceramic Igniter for the Quadrafire 800, 1000 and 1100i Pellet Stoves. Click on the photo to enlarge and view other angles.

NOTE: This is the Ceramic Igniter for the Ceramic burn pot ONLY. If you have the EZ-Clean Burn Pot, you will need the Loop Ignitor 812-3811. Click here to purchase.

When installing this igniter, it is very important that you do not touch the black heating element with your bare skin. The oils from your skin will penetrate the element and cause the igniter to burn or break. The warranty does NOT cover breakage.

Part # 812-0180 OEM Quadrafire Part

$50 at stove-parts-unlimited.com 6" Loop Igniter for Quadrafire part# 812-3811 - $50 - free shipping - 3-5 days shipping

Quadrafire Pellet Stove Ignitor, Loop, 18"

$77.00

Model: SRV7000-462-QF

Shipping Weight: 1lbs

Manufactured by: Quadra-Fire

THIS PART REPLACES PART# SRV7000-226

You may ALSO want Ceramic Wire Nuts: Part #812-0730-WHS

Installation Instructions can be found here

local copy of Quadra-Fire 1100-I ignitor installation

Replace Exhaust Gasket

The Woodshed Stove Shop

tues-fri

9 - 3pm

1215 S. 9th St.

Canon City, CO 81212

Quadrafire 1100i Flue flange Gasket $18.95

Quadrafire 1100i Flue Flange Gasket - Wing (812-1300) - Part number: 812-1300 $32.00 at stove-parts-unlimited.com/quadrafire

Quadra-Fire Flue Adapter Gasket 240-0850 - this looks like it will work $12.99 at amazon

Mountain View Hearth Products

Mailing Address:

3905 HWY 40

Columbia Falls, MT 59912

Physical Address:

3905 HWY 40

Columbia Falls, MT 59912

Phone:

406-272-9850

Monday - Friday 8AM - 5PM

Fax:

406-272-9851

E-mail:

support@stove-parts-unlimited.com

gasket paper, superwool plus, 2100F, Small Sheets, 15'' x 24'' x 1/8'', 4 pcs/pkg $48.50 at amazon

PRODUCT INFO: High temperature gasket paper rated to 2100F. Soft pliable material.

USE: Used on the oil, gas and wood fired boiler, furnaces, stoves, kilns, evaporators and forges as a gasket material. Often used to seal doors and access points. Easy to cut with a knife.

Size: 24 x 15 x 1/8’’, 4 Pcs/pkg

Made in the USA by Lynn Manfuacturing, Inc.

Lynn Pellet & Wood Stove Gasket Paper, 2100F rated, 10'' x 7'' x 1/8'' $10.75 at amazon

2260J USE: replacement gasket paper used when pre-cut gasket is not available. Also can be used a high temperature gasket paper in other applications.

Fits: gasket paper is big enough to fit nearly every wood stove or insert and can be cut using knife or scissors to the dimensions fo the orignical gasket.

SIZE: 10’’ x 7’’ x 1/8’’ thick

MATERIAL: Superwool Plus paper, which is flexible, strong, seals well & withstands 2100F. Superwool is an alternative to ceramic fiber with improved health and safety attributes. Superwool products do NOT carry a GHS health hazard warning label.

Made in the USA by Lynn Manfuacturing, Inc.

red RTV silicone

Permatex 81878 Ultra Copper Maximum Temperature RTV Silicone Gasket Maker, 3 oz. Tube $6.30 at amazon

Most advanced, high temp RTV silicone gasket available

Three times more oil resistant than conventional silicones; eight times more flexible than cut gaskets

Sensor-safe, low odor, and non-corrosive with superior adhesion

Temperature range -75F to 700F intermittent

Suggested Applications: Exhaust manifolds/headers, valve covers, oil pans, timing covers, water pumps, thermostat housings

J-B Weld 31314 Red High Temperature RTV Silicone Gasket Maker and Sealant - 3 oz. $5.89 at amazon

fel-pro gasket sheets

fel-pro

fel-pro

fel-pro

fel-pro

Rutland 600-Degree RTV Silicone Seal Tube, 2.7-Ounce, Super Red $15 at amazon

Web Research

jettlash1000 youtube Are Pellet Stoves Efficient?

Fel-Pro Gasket Sheets summitracing.com/search

Fel-Pro 2499 Gasket Material $16 at amazon

Fel-Pro 2499 Gasket Material $9 at summitracing

Brand: Fel-Pro

Manufacturer's Part Number: 2499

Part Type: Gasket Material, Sheets

Product Line: Fel-Pro Gasket Sheets

Summit Racing Part Number: FEL-2499

UPC: 084113855054

Gasket Sheet Material: Rubber/Fiber

Gasket Sheet Thickness (in): 0.063 in.

Gasket Sheet Length (in): 12.000 in.

Gasket Sheet Width (in): 28.500 in.

Fel-Pro 2499 Gasket Material $9 at jegs

Fel-Pro 2498 Gasket Material $21 at amazon

Fel-Pro Gasket Sheets 2498 $14 at summitracing

Brand: Fel-Pro

Manufacturer's Part Number: 3025

Part Type: Gasket Material, Sheets

Product Line: Fel-Pro Gasket Sheets

Summit Racing Part Number: FEL-3025

UPC: 084113855443

Gasket Sheet Material: Karropak

Gasket Sheet Thickness (in): 0.063 in.

Gasket Sheet Length (in): 18.000 in.

Gasket Sheet Width (in): 36.000 in.

Brand: Fel-Pro

Manufacturer's Part Number: 2498

Part Type: Gasket Material, Sheets

Product Line: Fel-Pro Gasket Sheets

Summit Racing Part Number: FEL-2498

UPC: 084113850660

Gasket Sheet Material: Pro-Ramic

Gasket Sheet Thickness (in): 0.047 in.

Gasket Sheet Length (in): 28.000 in.

Gasket Sheet Width (in): 12.000 in.

Ash Vacuum

Shop-Vac® Ash Dry Vacuum - 4041300 - Model CAV150 - Lowe's Sku. - 781443

Cold vacuum only?

Shop-Vac 5 Gal Ash Dry Vacuum shopvac.com/product/shop

Shop-Vac 5-Gallon Replacement HEPA Filter Item # 619289 Model # 9032900 lowes.com/pd/Shop

Shop-Vac® 5.0 Gallons* Ash Dry Vacuum Catalog No. - 4041300 Model No. - CAV150 Lowe's Sku. - 781443 shopvacstore.com/shop-vac-ash-vacuum

PowerSmith Ash Vacuum MODEL #: PAVC102

PowerSmith Ash Vacuum MODEL #: PAVC102 powersmithtools.com/portfolios

review PowerSmith PAVC102

PowerSmith 4 Gal. Dry Ash Canister Vacuum $100 at homedepot

PowerSmith PAVC102 10 Amp 4 Gallon Ash Vacuum with 2 Ash Filters, Silver $114.96 at amazon

PowerSmith™ PAVC102 Ash Vacuum is specifically designed to clean warm and cool ash out of fireplaces, wood stoves, pellet stoves, and barbecue grills. The washable, replaceable and fire-resistant 2-layer filter system, together with the Heat-resistant metal hose and metal canister, stands high temperature and prevents fire hazards.

November 2017 Troubleshooting

Problem: Fire does not start.

Symptom: Exhaust blower does not run.

Blower #2 - Negative Draft Blower

User manual p.1614 Blower #2 (Negative Draft Blower)

This blower creates a negative pressure (vacuum) in the firebox. It extracts all of the exhaust out of the firebox and sends it into the venting system. The blower is located on the left side of the insert. When the insert is pulled out onto the hearth, the blower is accessible through a removable access panel.

</h4>p13.4 VENTING SYSTEM</h4>

The venting system should be inspected and cleaned at least once a year, or more often depending upon the quality of your fuel. If you are experiencing nuisance shutdowns, check for a clogged exhaust system. If the exhaust is restricted, the vacuum safety switch will shut the feed motor off (the red light will remain on). You can clean the venting system without removing it from the insert by opening the small hinged access door, located on top of the exhaust blower housing. Using a small vacuum attachment, vacuum the exhaust housing

p13.6 - BLOWERS

There are three blowers in this insert: an exhaust blower that evacuates the exhaust out of the firebox, and two convection air blowers that delivers heat into the room. THESE BLOWERS REQUIRE NO LUBRICATION.

A. The exhaust blower is located at the left rear side of the insert. It should be inspected during the annual cleaning of the exhaust system. The exhaust blower impellers can be inspected periodically by using the exhaust blower cleanout door.

B. The larger convection blower is located on the front left side of the insert, and is accessible by removing the front left panel. The impeller on this blower should be cleaned at least once a year. You can do this without removing the blower. Simply brush and vacuum the impeller area.

C. The small convection blower is located at the rear right side of the insert. When the insert is pulled out onto the hearth, it is accessible through a removable access panel. The impeller on this blower should also be cleaned at least once a year, and can also be cleaned in place.